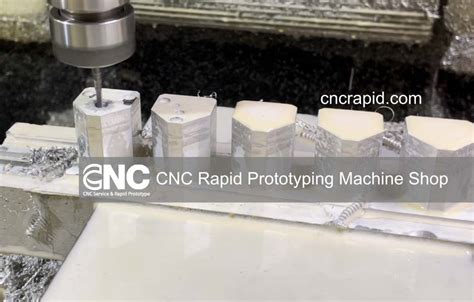

cnc machine prototype On-demand CNC machining service for rapid prototyping and production parts, through a network of specialized, experienced and thoroughly vetted local and global CNC machine shops. CNC . If you have a set of calipers you can measure the thickness of the existing metal and then order what you need. Here's some of the common gauges and corresponding thickness of sheet steel: GA.

0 · rapid prototype machine shop

1 · prototype cnc machine shop manufacturer

2 · cnc prototyping near me

3 · cnc prototyping cost

4 · cnc prototype machinist

5 · cnc machining rapid prototype manufacturer

6 · cnc machining prototype service

7 · 3d printing prototype company

CAD CAM software is used by hobbyists and professionals across a wide range of applications, from CNC machining to dentistry. But how do you go about finding the best CAD CAM software? In this guide I’ll share my first-hand experience with all the top CAD CAM solutions (both free and paid), comparing them across their strengths and weaknesses .

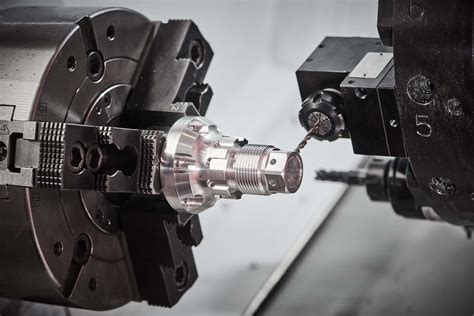

CNC machining is an automated manufacturing process that transforms a solid block or rod of material into a part using end mills. The end mills are controlled by software (G-code) which .

On-demand CNC machining service for rapid prototyping and production parts, through a network of specialized, experienced and thoroughly vetted local and global CNC machine shops. CNC .

rapid prototype machine shop

prototype cnc machine shop manufacturer

Get instant online quote for your metal or plastic CNC machined parts, from rapid prototyping to production. Tolerance down to 0.001 inches. Choose from 100+ materials, 60+ surface . CNC prototype machining is a form of subtractive manufacturing wherein the parts are manufactured by the removal of material from a single piece of stock using computer .Read on to see how CNC machining can be used for prototyping, focusing on processes, advantages, and applications. What is CNC Machining? CNC machining is a subtractive manufacturing process, meaning the material is .This guide explores the fundamentals of CNC prototype machining, its process, benefits, and applications. What is CNC Prototype Machining? CNC prototype machining is a manufacturing .

Employ 3D printing, CNC machining, and injection molding. Quickly iterate and refine designs with high accuracy. Ensure prototypes meet your exact specifications.Whether you need a single prototype or a large production run, TENGHUI is your trusted partner for high-quality CNC machining parts. We’re dedicated to supporting your project at every stage, offering customized solutions that meet . Unlike traditional prototyping methods, CNC prototype machining offers unparalleled precision and repeatability. The process involves the removal of material from a solid block, resulting in prototypes that closely mimic the .3ERP is the known as the world's best rapid manufacturing company, offering rapid prototyping & low volume production including CNC machining, vacuum casting, prototype injection molding.

Making custom machined parts needed for nearly every industry, including automotive, robotics, medical, aerospace, electronics and industrial. 3ERP provides CNC machining services and offers custom CNC quotes on various of materials ranging from commodity aluminum, steel, stainless steel, ABS, acetal to advanced titanium, Inconel, and . CNC prototype machining is the go-to process for designing parts and models in the automotive industry. The automotive industry requires gears and parts with ultra-tight tolerances. CNC machining prototypes can fulfill this requirement, unlike many other methods.The intricate nature of the parts created using foam CNC machining allows for precise measurements to tight tolerances that are usually impossible with other methods. Additionally, foam CNC machining services can produce highly detailed models and prototypes for product development and testing.

Quality testing and inspection in CNC machining applications represent a critical phase, ensuring every machined component meets the high standards of precision and excellence. This article dives into the intricate world of quality testing and inspection, elucidating its significance, methodologies, and the innovations shaping its future. Discover how to create plastic prototypes using 3D printing, CNC machining, injection molding, and vacuum casting. Choose the best method for faster product development. How Does Production CNC Machining Work? The process of production CNC machining is a symphony of six precise, automated steps, from raw material to finished product. Material Selection and Preparation: Choosing the right material—whether metal, composites, or plastics—is critical.

CNC drilling and thread tapping are distinct operations within CNC machining. CNC drilling involves creating precise holes in a workpiece using a drill bit, focusing on hole sizes and depths for assembly purposes or further machining.Aluminum is one of the most popular machining materials thanks to its workability, strength, and versatility. What’s more, its low cost makes it perfect for prototypes, end-use products, and custom tools for molding. From standard grades like 6061 to high-quality aerospace grades like 7075, we have an aluminum alloy for every CNC machining . It also discusses various effective methods for creating metal prototypes: CNC machining, 3D printing (additive manufacturing), sheet metal forming, casting and extrusion. 3ERP has the capability to combine multiple processes and offer the best solution for your metal prototype needs.3ERP is the known as the world's best rapid manufacturing company, offering rapid prototyping & low volume production including CNC machining, vacuum casting, prototype injection molding.

cnc prototyping near me

Making custom machined parts needed for nearly every industry, including automotive, robotics, medical, aerospace, electronics and industrial. 3ERP provides CNC machining services and offers custom CNC quotes on various of materials ranging from commodity aluminum, steel, stainless steel, ABS, acetal to advanced titanium, Inconel, and . CNC prototype machining is the go-to process for designing parts and models in the automotive industry. The automotive industry requires gears and parts with ultra-tight tolerances. CNC machining prototypes can fulfill this requirement, unlike many other methods.The intricate nature of the parts created using foam CNC machining allows for precise measurements to tight tolerances that are usually impossible with other methods. Additionally, foam CNC machining services can produce highly detailed models and prototypes for product development and testing. Quality testing and inspection in CNC machining applications represent a critical phase, ensuring every machined component meets the high standards of precision and excellence. This article dives into the intricate world of quality testing and inspection, elucidating its significance, methodologies, and the innovations shaping its future.

Discover how to create plastic prototypes using 3D printing, CNC machining, injection molding, and vacuum casting. Choose the best method for faster product development. How Does Production CNC Machining Work? The process of production CNC machining is a symphony of six precise, automated steps, from raw material to finished product. Material Selection and Preparation: Choosing the right material—whether metal, composites, or plastics—is critical.

CNC drilling and thread tapping are distinct operations within CNC machining. CNC drilling involves creating precise holes in a workpiece using a drill bit, focusing on hole sizes and depths for assembly purposes or further machining.

Aluminum is one of the most popular machining materials thanks to its workability, strength, and versatility. What’s more, its low cost makes it perfect for prototypes, end-use products, and custom tools for molding. From standard grades like 6061 to high-quality aerospace grades like 7075, we have an aluminum alloy for every CNC machining .

cnc prototyping cost

cnc prototype machinist

cnc machining rapid prototype manufacturer

cnc machining prototype service

An alternative would be to use a common 4" metal box (21 cubic inches) with a single gang mud ring. If using Romex, use cable clamps to enter a knockout hole. See pictures below.

cnc machine prototype|3d printing prototype company